All customerprocesses that use gases - Strategic application technology

Nested Applications

Nested Applications

Categories Navigation

Asset Publisher

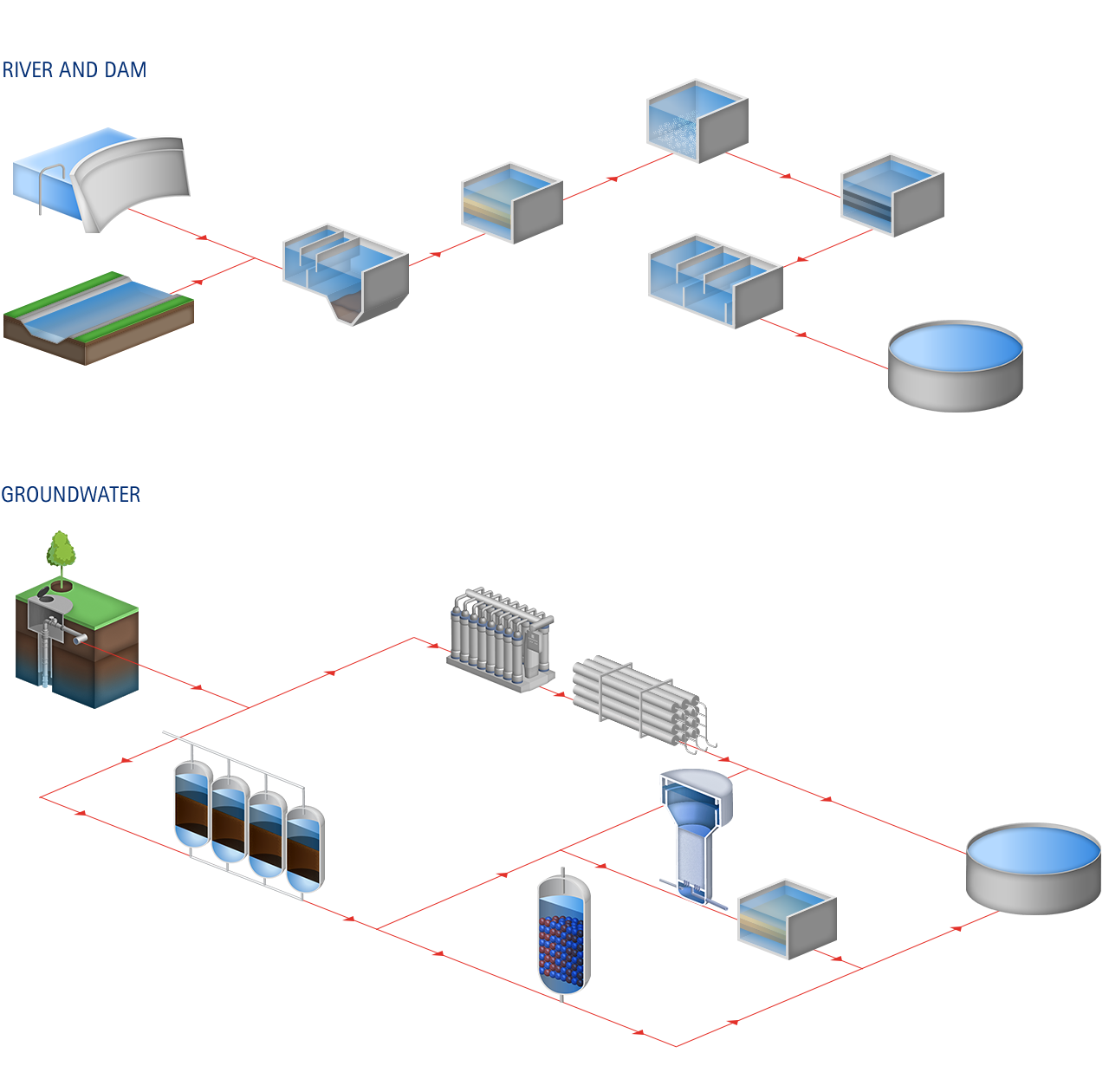

Drinking water

Gases help to produce drinking water of perfect quality. Nowadays, modern treatment facilities largely avoid the use of poisonous or corrosive chemicals. Instead two industrial gases are increasingly used: oxygen and carbon dioxide, both a natural component of the water cycle.

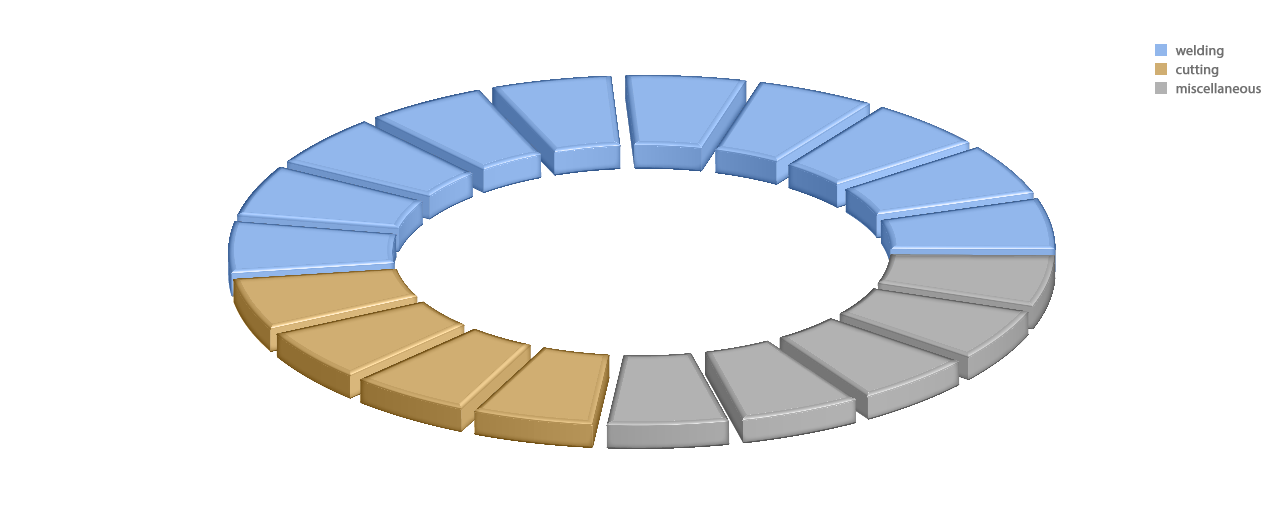

Welding and cutting processes

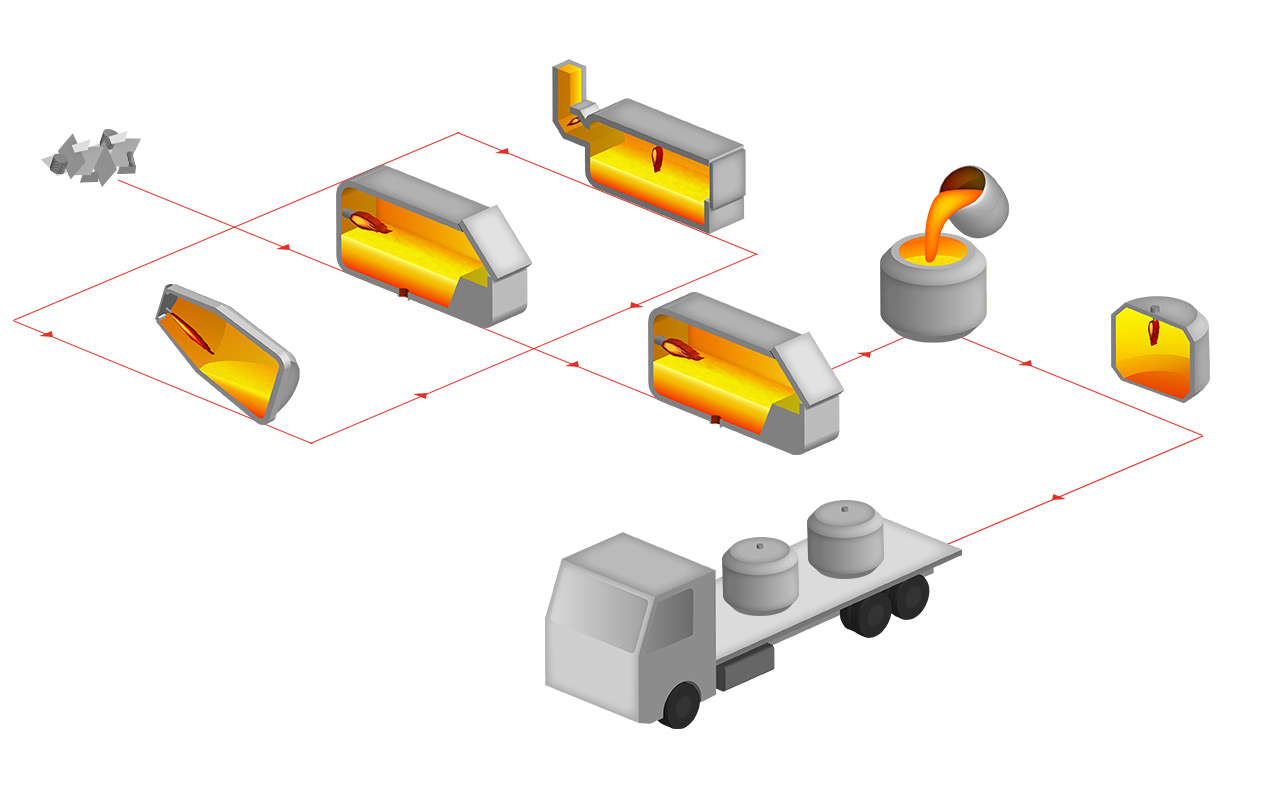

Aluminum melting process

Just over 50% of aluminum products are produced from recycled secondary aluminum, with the main process steps being scrap conditioning, melting and casting. Depending on the contamination and bulk of the scrap, various types of furnace are used during melting: rotary drum furnaces, chamber furnaces or shaft furnaces. To remove impurities, the aluminum melt is cleaned by gas purging. This takes place in holding furnaces or specially designed ladle stations. In the case of the melt being transported in ladles on vehicles to another processing location, it is necessary to preheat the ladles with burners.

bakery products

The product variety of baked goods ranges from rolls to cake variations. Messer's application technology know-how in this segment is just as extensive. This starts with silo inerting during raw material storage, continues with cooling processes during kneading and extends to the transport of chilled or frozen baked goods.

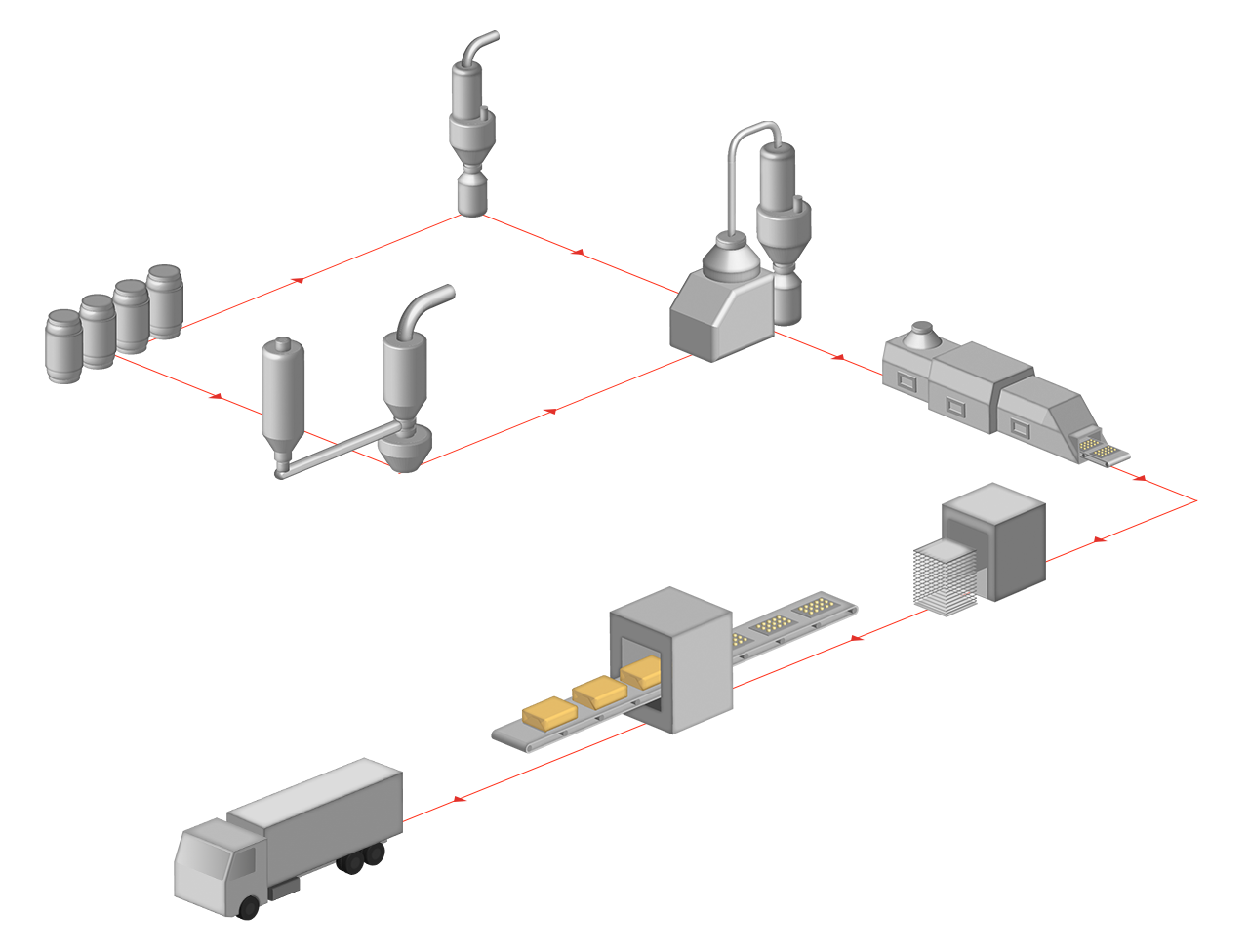

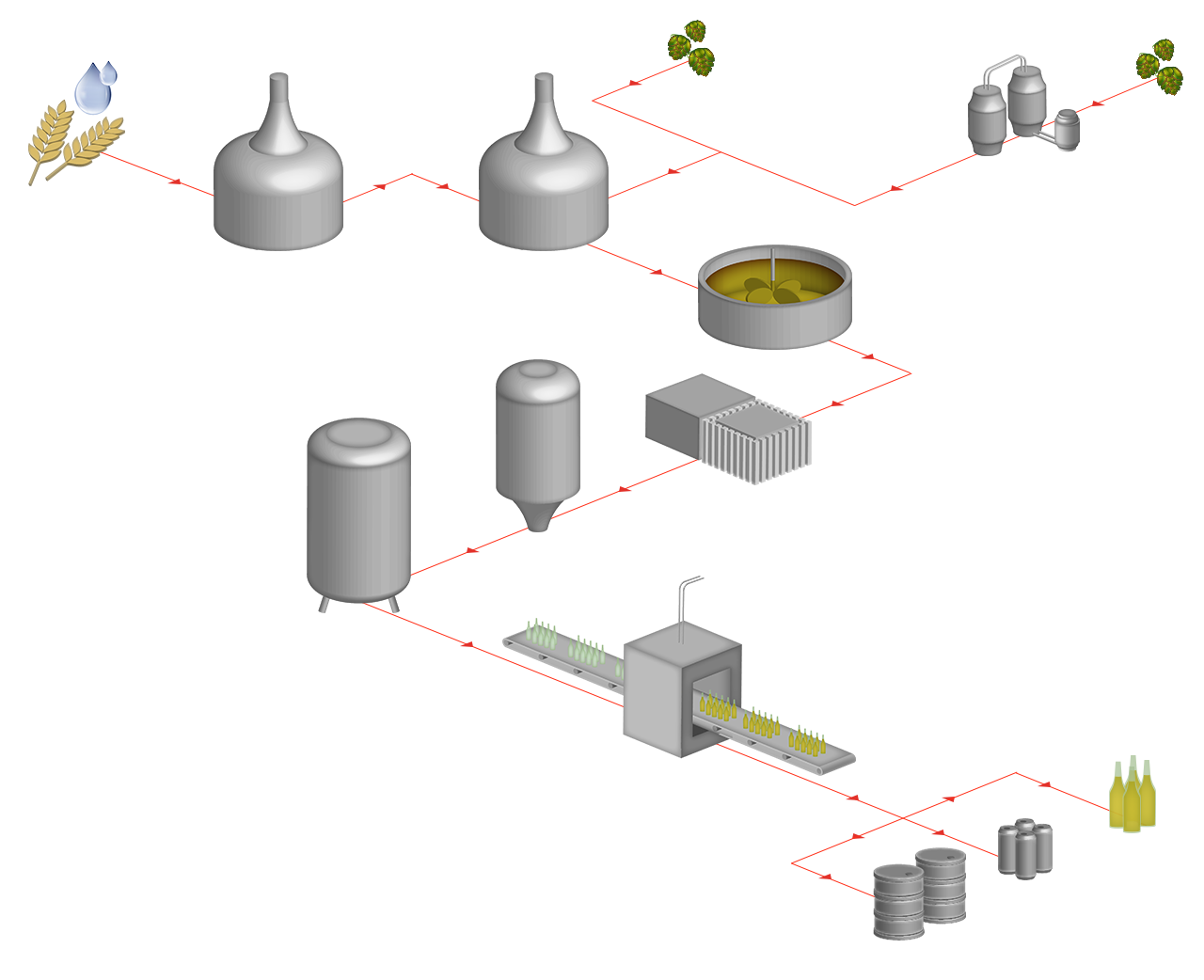

Beer process chart

The brewing process starts, strictly speaking, with the selection of raw materials. According to the "German Purity Law", in Germany these can only consist of water, hops, malt and yeast. In further carefully coordinated process steps, the beer is then produced according to taste and type. Various gas applications are used to optimise the production process: the most well-known application being the carbonating of the beer by means of carbon dioxide. But gases from Messer are also used when inerting product tanks to displace unwanted oxygen or during beer filling.