All customerprocesses that use gases - Strategic application technology

Nested Applications

Nested Applications

Categories Navigation

Asset Publisher

Heat treatment iron & steel in the iron & steel sector

Many metals acquire their optimum surface quality and the required mechanical properties through suitable heat treatment. Here, gases are an indispensable aid. Messer Group has developed a wide range of special processes to make the heat treatment of metals more controllable, reproducible, and economical.

The term heat treatment describes a process in which a work piece or part of a work piece is intentionally subjected to a specific time-temperature sequence. In some instances, the work piece may additionally be subjected to other physical and/or chemical influences. The aim of heat treatment is to impart properties to a work piece which are required for further processing steps or for the intended application.

This definition covers all thermal, thermo-chemical and thermo-mechanical processes for the treatment of work pieces with which mechanical material properties are to be selectively changed. Furthermore, the appearance of the surface of work pieces can be influenced. These properties are optimized by structural transformations on the surface or in the entire work piece and by chemical changes on the surface.

Heat treatment takes place in furnaces that are temperature controlled (heating, soaking and cooling steps), usually using a process gas atmosphere to prevent, e.g. undesirable discoloration or to alter the surface chemically. The influenceable properties are, e.g. deformability, residual stresses, hardness, toughness and surface condition.

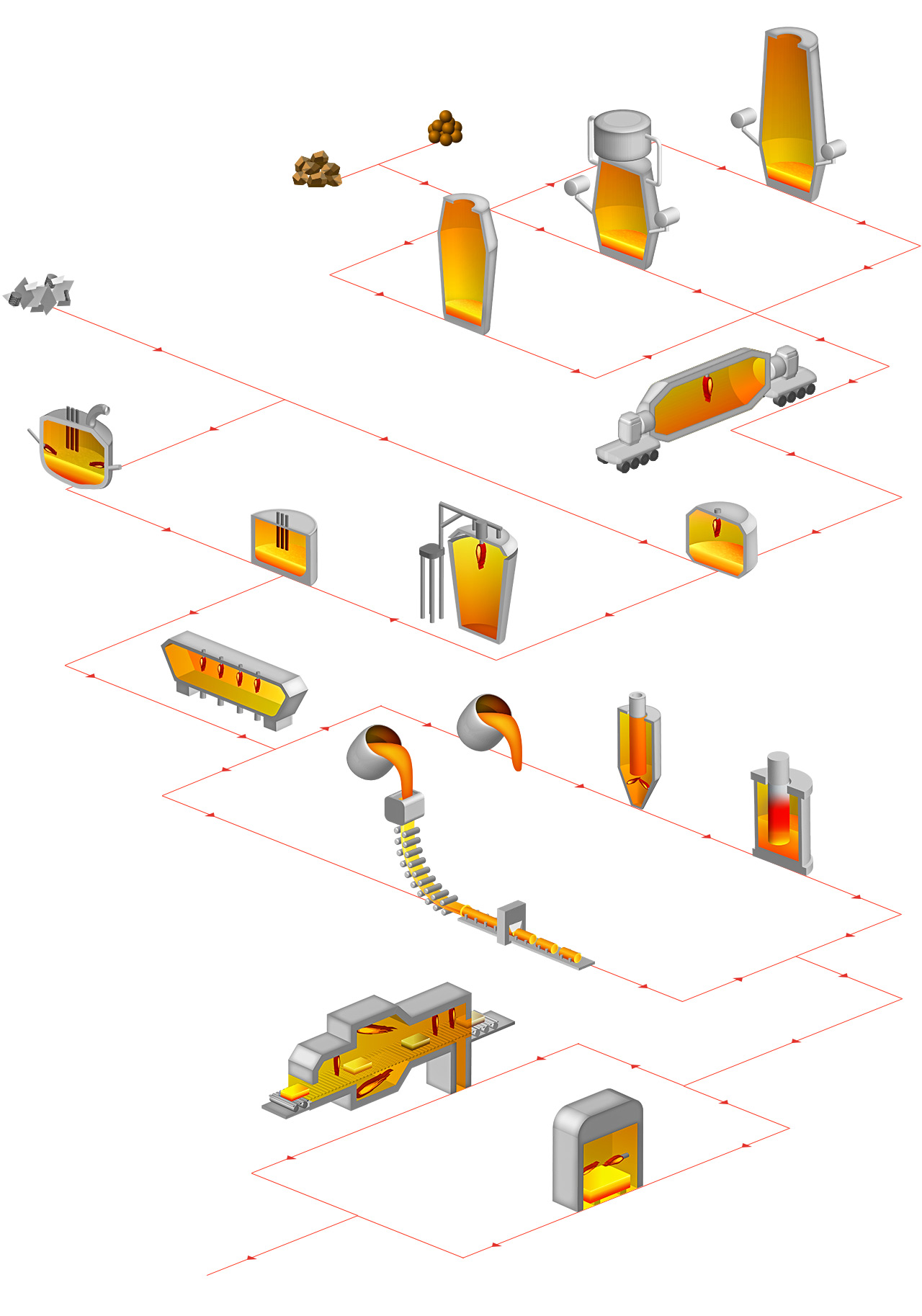

Foundries processes

As far back as 5000 BC copper and gold were being used to cast artefacts; and iron casting was started in 500 BC. Today, non-ferrous foundries worldwide annually produce around 20 m tonnes; and grey cast iron, malleable cast iron, spheroidal graphite iron and cast steel foundries approx. 70 m tonnes of raw and finished components for the automobile, engineering, shipbuilding, hydraulics and construction industries.

Here we will be referring to iron and steel foundries. The main raw material for products is recycled scrap metal and pig iron.

Gases and technologies for Heat treatment processes

Many metals and advanced ceramics acquire their optimum surface quality and the required mechanical properties through suitable heat treatment. Here, gases are an indispensable aid. Messer Group has developed a wide range of special processes to make the heat treatment of metals and technical ceramics more controllable, reproducible, and economical.

The term heat treatment describes a process in which a work piece or part of a work piece is intentionally subjected to a specific time-temperature sequence. In some instances, the work piece may additionally be subjected to other physical and/or chemical influences. The aim of heat treatment is to impart properties to a work piece which are required for further processing steps or for the intended application.

This definition covers all thermal, thermo-chemical and thermo-mechanical processes for the treatment of work pieces with which mechanical material properties are to be selectively changed. Furthermore, the appearance of the surface of work pieces can be influenced. These properties are optimized by structural transformations on the surface or in the entire work piece and by chemical changes on the surface.

Heat treatment takes place in furnaces that are temperature controlled (heating, soaking and cooling steps), usually using a process gas atmosphere to prevent, e.g. undesirable discoloration or to alter the surface chemically. The influenceable properties are, e.g. deformability, residual stresses, hardness, toughness and surface condition.

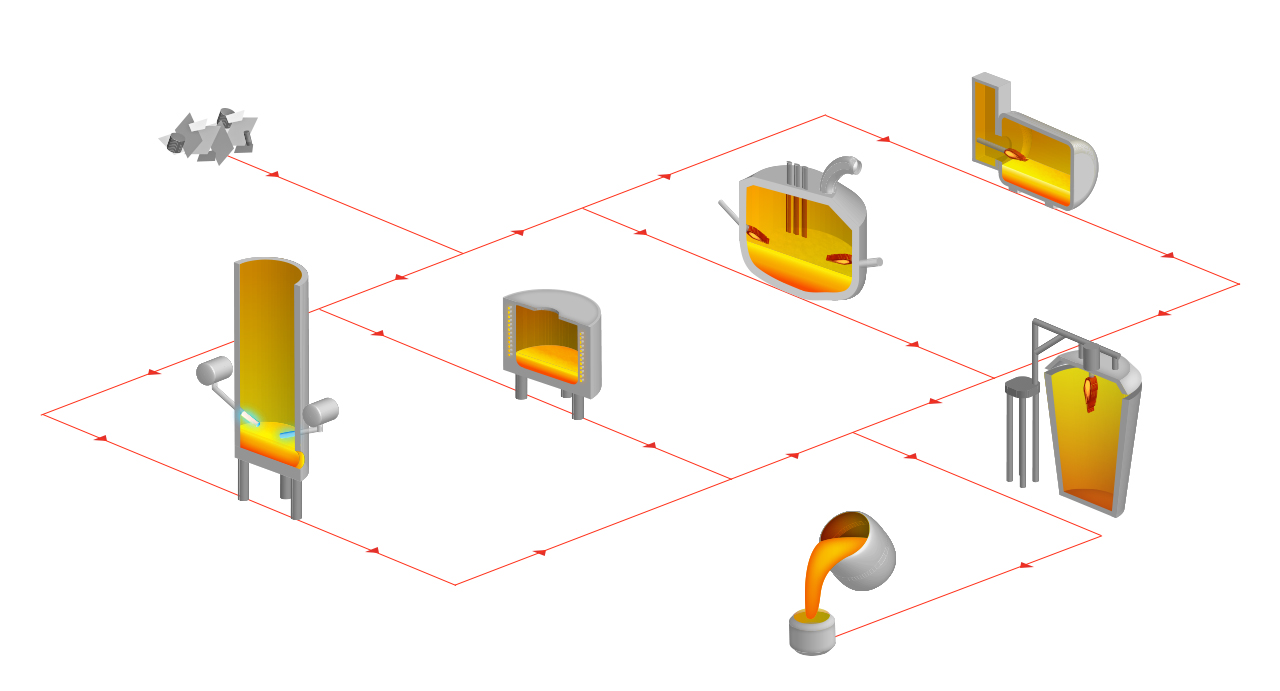

Steel processes

Is it possible to imagine a world without steel? No, steel is one of the essential materials in our society and we encounter it every day, whether as a paper clip, means of transportation or skyscrapers. The period of mass steel production began in the mid-19th century with developments from Bessemer, Thomas and Siemens - Martin. The advantage of pure oxygen for refining was already known at that time, but only became technically manageable 100 years later. Steel producers, research institutes and suppliers are working worldwide to improve product properties and manufacturing. Steel is made from iron ore or scrap.