All customerprocesses that use gases - Strategic application technology

Nested Applications

Nested Applications

Categories Navigation

Asset Publisher

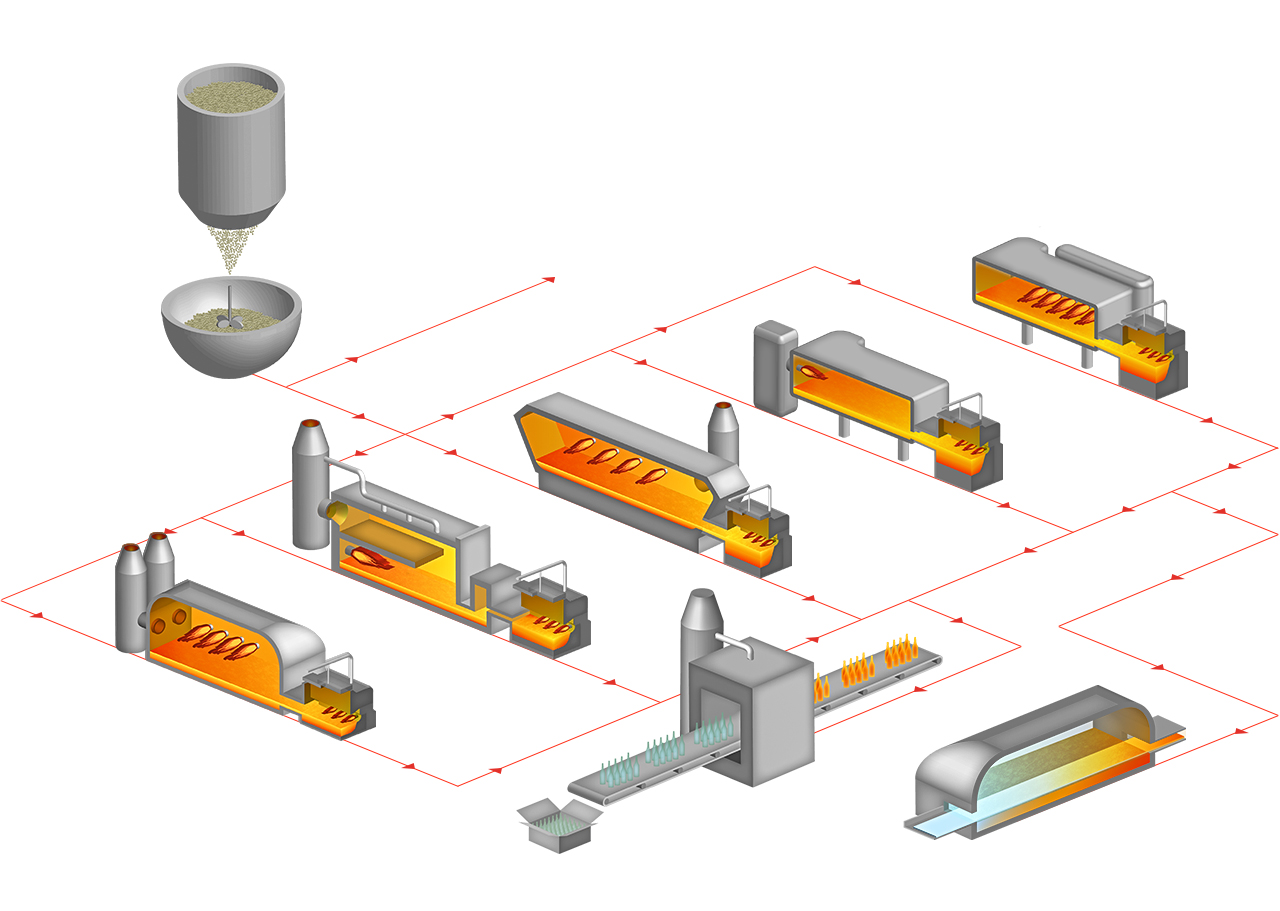

Glass production process chart

The definition of glass according to the American Heritage Dictionary is:

- Any of a large class of materials with highly variable mechanical and optical properties that solidify from the molten state without crystallization, are typically made by silicates fusing with boric oxide, aluminium oxide, or phosphorus pentoxide, are generally hard, brittle, and transparent or translucent, and are considered to be supercooled liquids rather than true solids.

Heat treatment iron & steel in the iron & steel sector

Many metals acquire their optimum surface quality and the required mechanical properties through suitable heat treatment. Here, gases are an indispensable aid. Messer Group has developed a wide range of special processes to make the heat treatment of metals more controllable, reproducible, and economical.

The term heat treatment describes a process in which a work piece or part of a work piece is intentionally subjected to a specific time-temperature sequence. In some instances, the work piece may additionally be subjected to other physical and/or chemical influences. The aim of heat treatment is to impart properties to a work piece which are required for further processing steps or for the intended application.

This definition covers all thermal, thermo-chemical and thermo-mechanical processes for the treatment of work pieces with which mechanical material properties are to be selectively changed. Furthermore, the appearance of the surface of work pieces can be influenced. These properties are optimized by structural transformations on the surface or in the entire work piece and by chemical changes on the surface.

Heat treatment takes place in furnaces that are temperature controlled (heating, soaking and cooling steps), usually using a process gas atmosphere to prevent, e.g. undesirable discoloration or to alter the surface chemically. The influenceable properties are, e.g. deformability, residual stresses, hardness, toughness and surface condition.

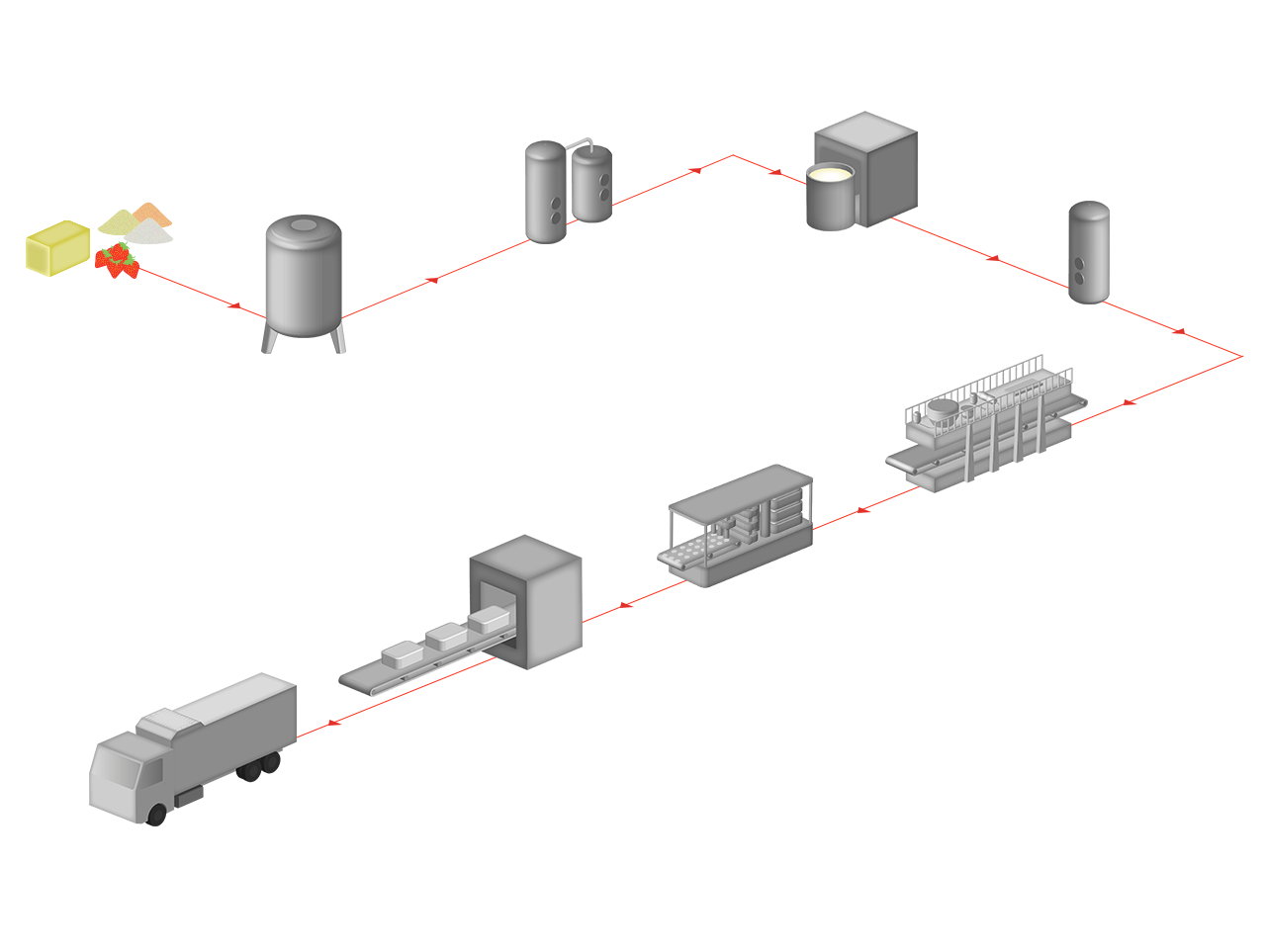

Ice cream process chart

Due to the many different types of product, the production of ice cream is particularly varied. In addition to cooling, probably the most obvious gas application in this segment, other processes such as chocolate coating, surface hardening and pelletising are also carried out with the use of gases.

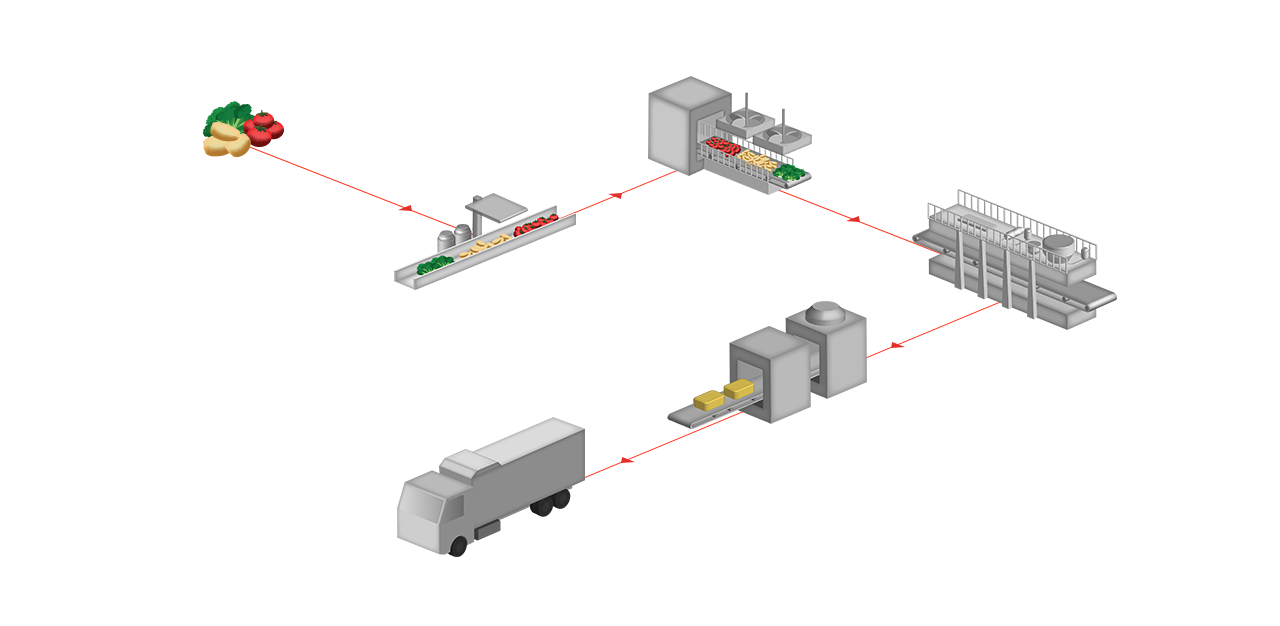

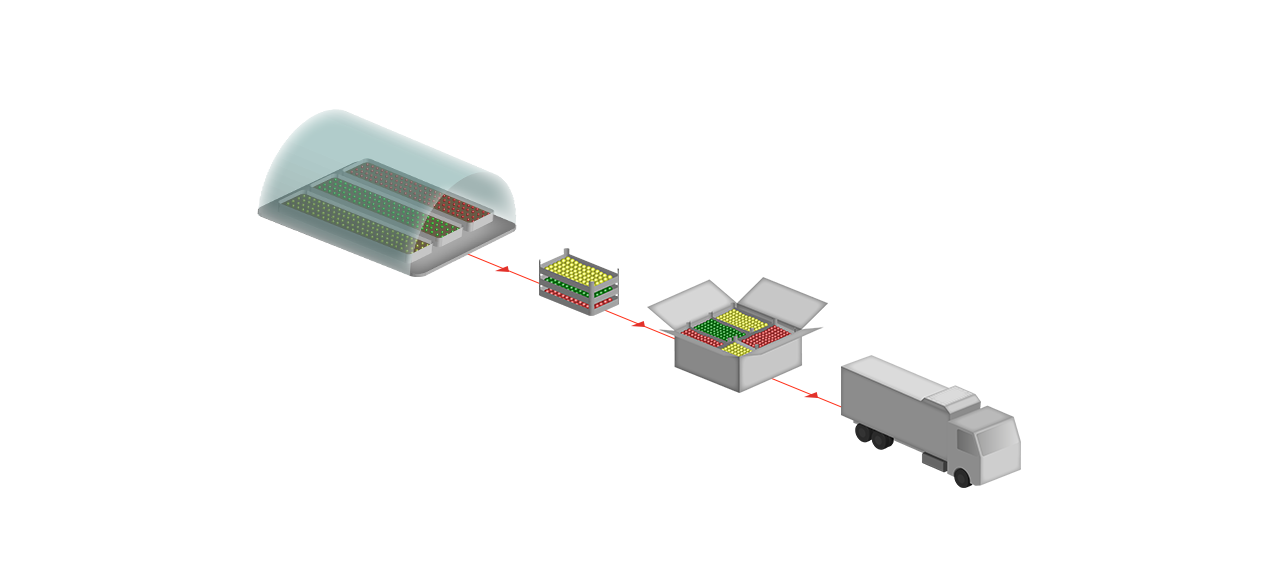

Vegetables and fruits process

The processing of fruit and vegetables consists of many individual steps. After cultivation and harvesting, fruit and vegetables are, depending on the desired end product, sorted, peeled and cut, cooled, and packaged until finally being transported to supermarkets.

Green house process chart

Plants are cultivated in heated or unheated greenhouses with their growth supported through CO2 fertilisation and O2 enrichment of the irrigation water. Ripening gases are used for climacteric fruit; these can specifically influence the ripening process of fruit which has already been harvested.