All customerprocesses that use gases - Strategic application technology

Nested Applications

Nested Applications

Categories Navigation

Asset Publisher

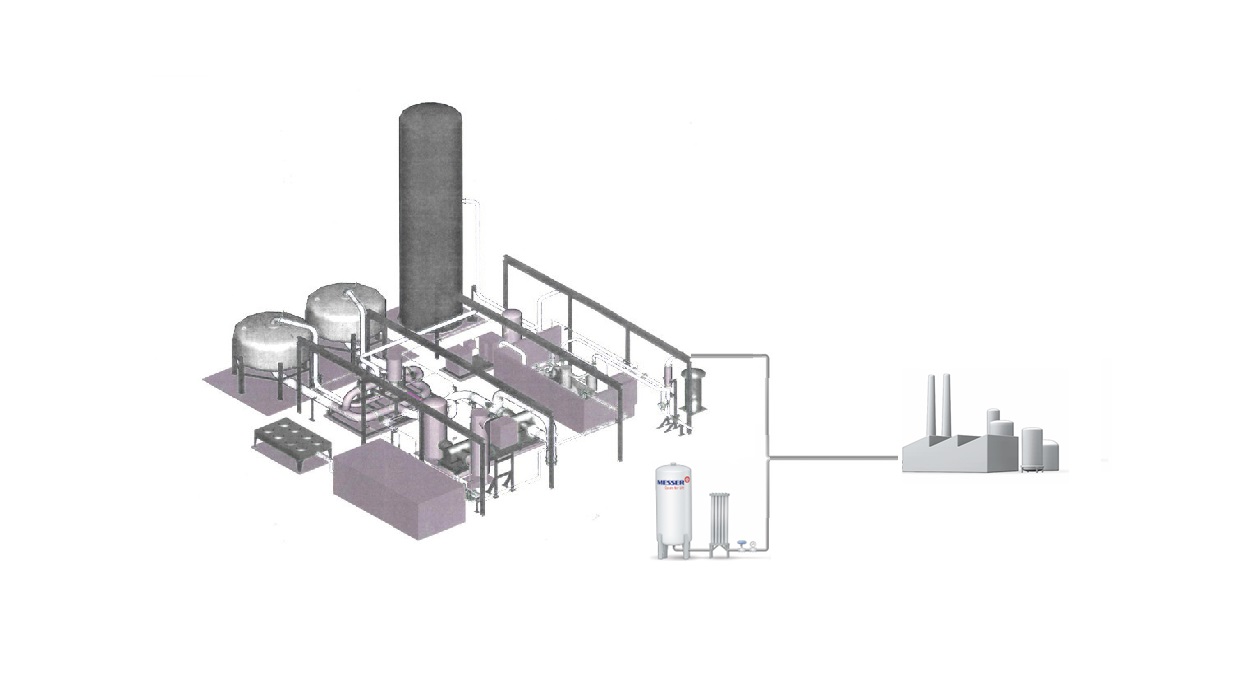

Sulphite process paper

The sulphite process is an industrial process to produce wood pulp suitable for wood low in resin and silicic acid.The advantages of this process are above all the very efficient delignification, the good bleachability, the high reactivity during further processing and low investment costs. In the sulphite process, the wood fibres are digested in an acidic or neutral medium. In the process, the lignin is subjected to sulphonation and is thereby converted into a water-soluble salt which can be removed from the cellulose. The by-product lignosulphonates are either commercially recovered or incinerated (recovery). In case of recovery the black liquor separated from the fibres during pulp washing is evaporated and burned in the recovery boiler using oxygen. The very light pulps produced in this way are today used almost exclusively for the production of chemical cellulose or paper. To produce one tonne of pulp you need about five cubic metres of wood and 90 kilograms of sulphur.

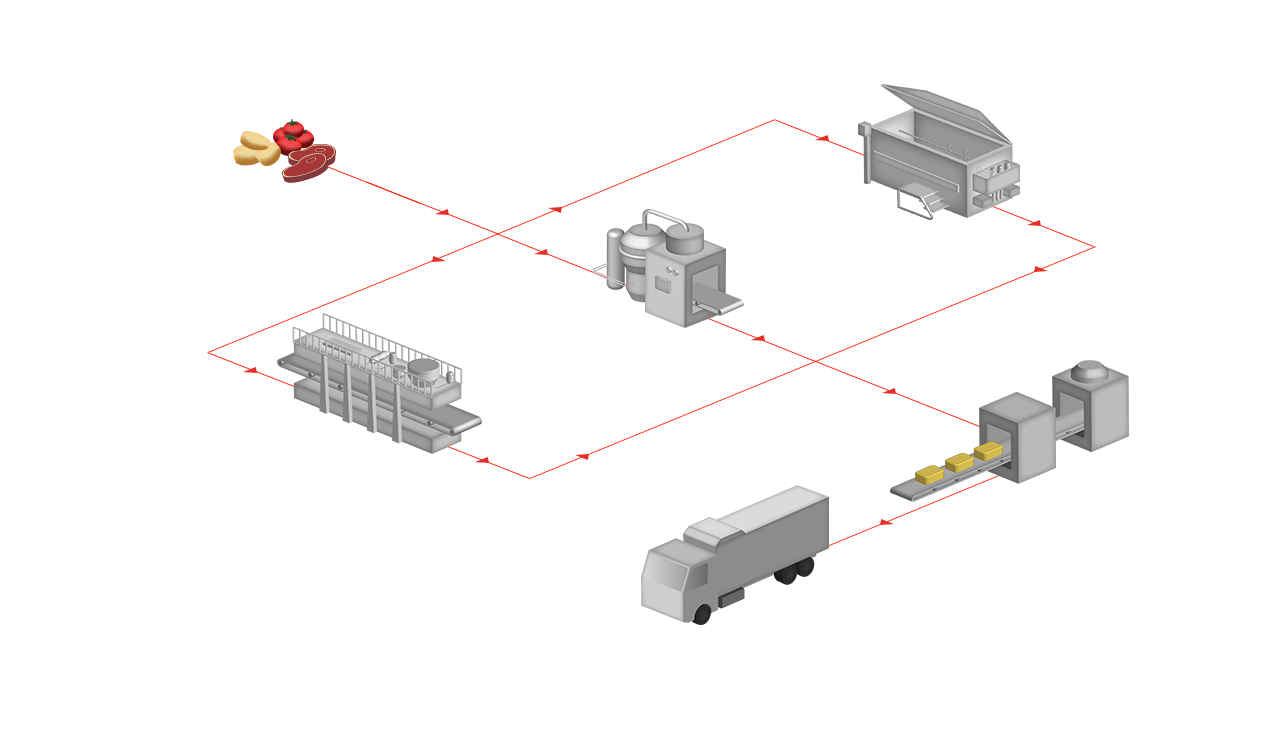

Ready made meals

Ready-made meals make cooking easier as the consumer is freed of any preparation, except for the heating of the food. The varied range of ready-made meals also reflects the complexity of the manufacturing process. Gases from Messer are used in many of the individual process steps. These include the mixing, cooling, freezing and packaging of the products.

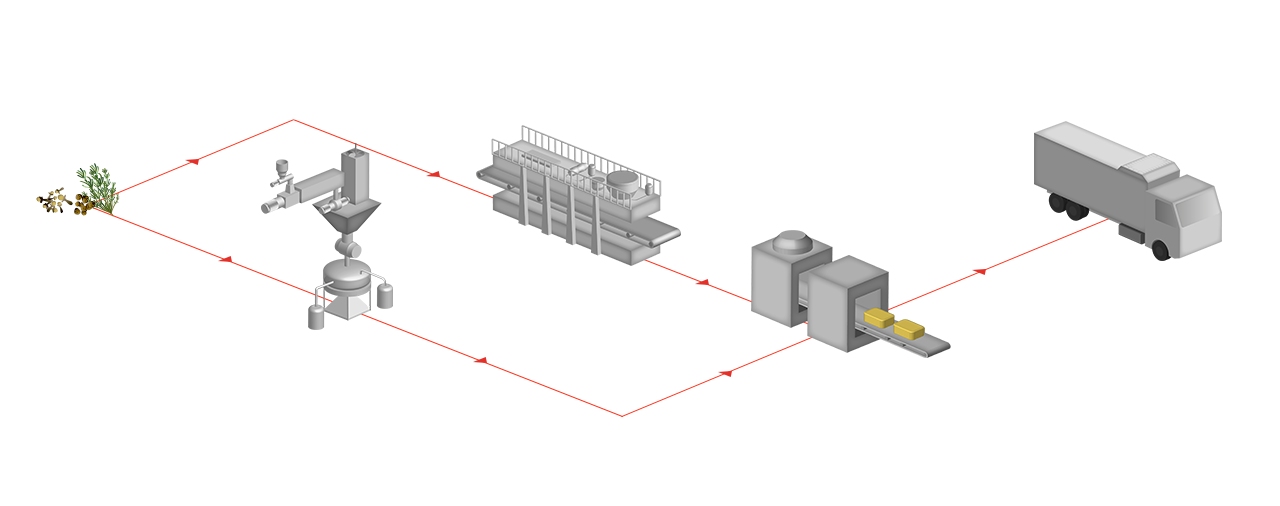

Spices and herbs process chart

Herbs and spices have become an integral part of our food. During their processing they are often ground, cooled or frozen and packaged. Gases from Messer play a role in many of these applications.

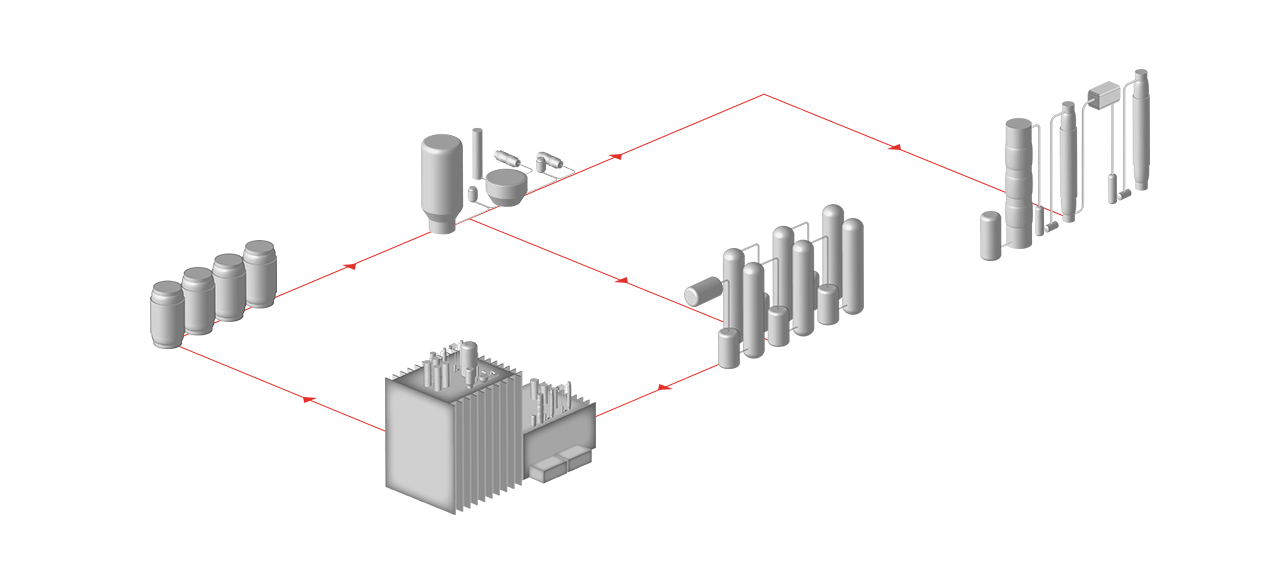

The VPSA Oxygen generator production line consists of the main technological equipment: