All customerprocesses that use gases - Strategic application technology

Nested Applications

Nested Applications

Categories Navigation

Asset Publisher

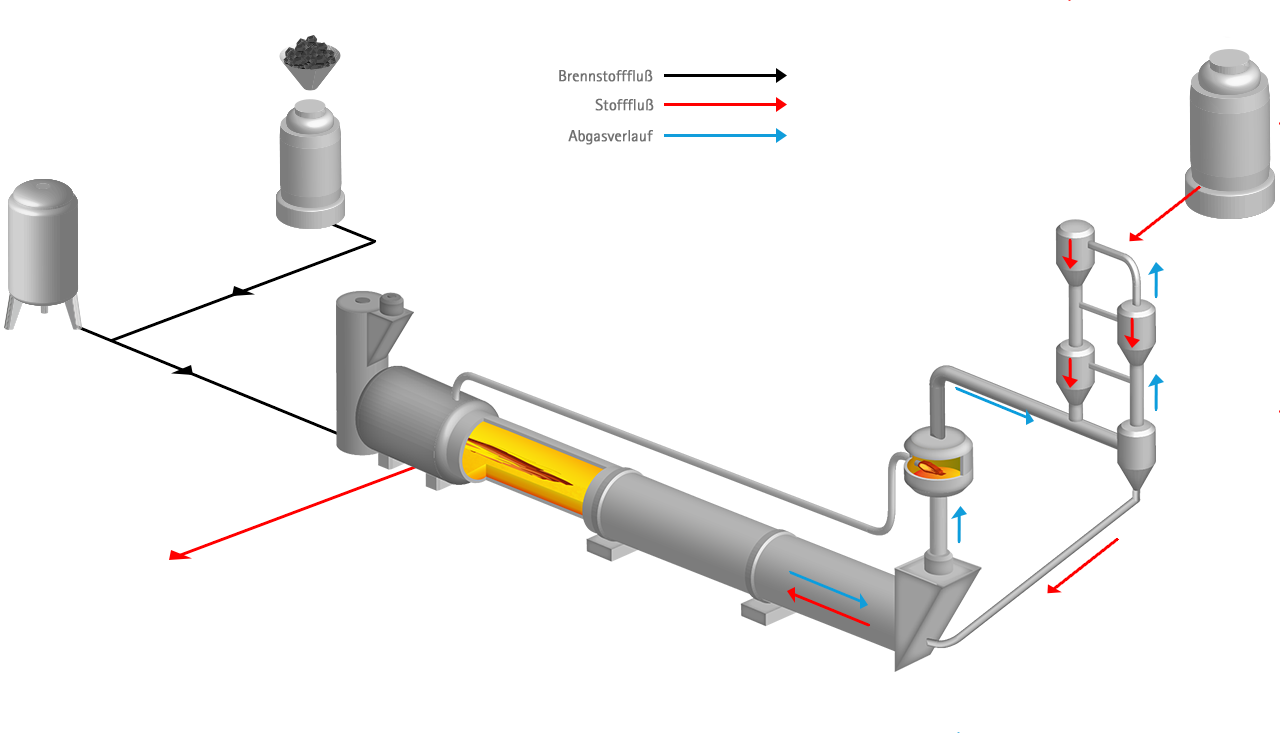

Cement process chart

The main raw materials for cement manufacture are limestone and lime marl. Grinded cement is a hydraulic binder, and with the addition of water hardens in air. In the form of mortar and concrete it is an indispensable material in the construction industry. Cement is primarily produced using a dry process with rotary kilns and multistage cyclone pre-heaters with or without pre-calciners. Production is energy-intensive and costly. Depending on the quality, temperatures of up to 1450°C have to be reached in the rotary kiln. To optimise energy costs, low caloric secondary fuels are becoming increasingly important.

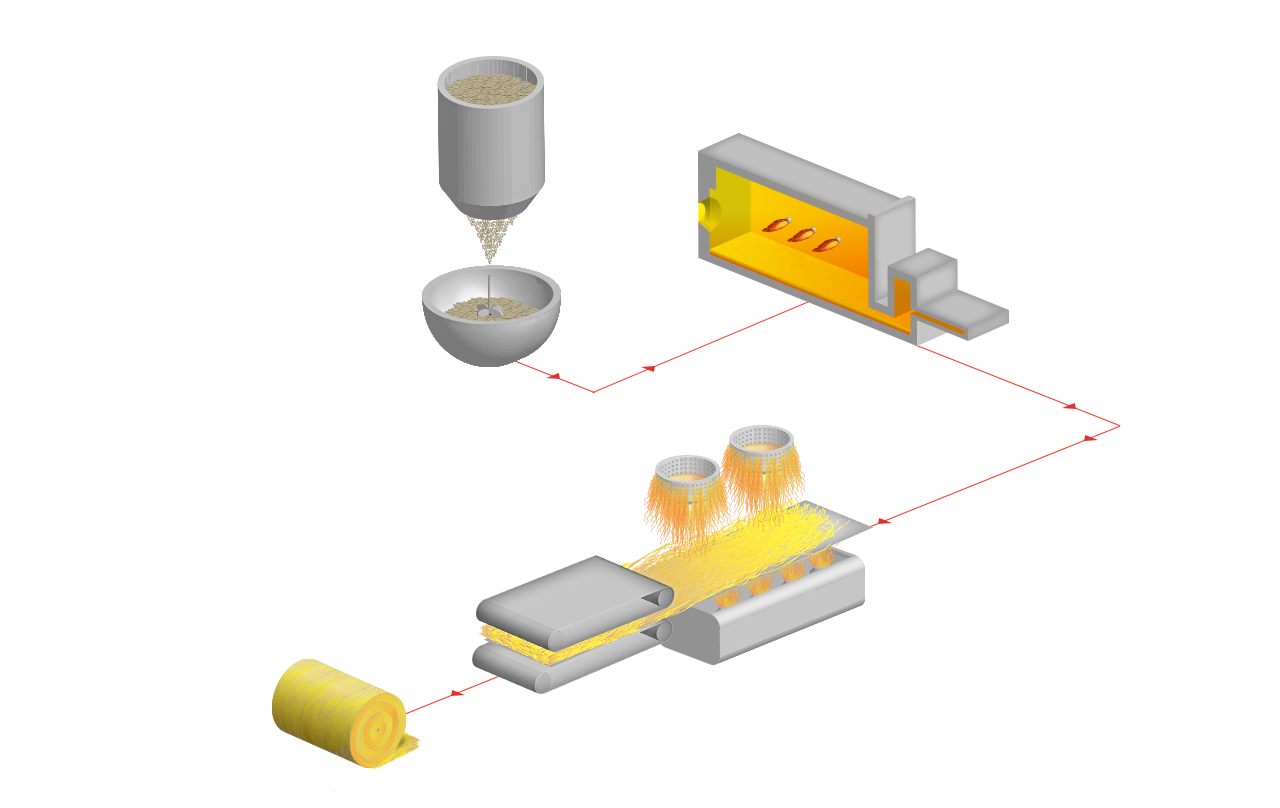

Glass wool production process

Mineral wool, also known as mineral fiber, mineral cotton, man-made mineral fibre (MMMF), and man-made vitreous fiber (MMVF), is a general name for fiber materials that are formed by spinning or drawing molten minerals (or "synthetic minerals" such as slag and ceramics). The nomenclature of these wool products is simply the parent/raw material name in prefix to wool. Wool from glass is glass wool, wool from rock is stone wool and so on. Specific mineral wool products are stone wool and slag wool. Europe also includes glass wool which, together with ceramic fiber, are completely man-made fibers. Applications of mineral wool include thermal insulation, filtration, soundproofing, and hydroponic growth medium.

Typical mineral wool composition

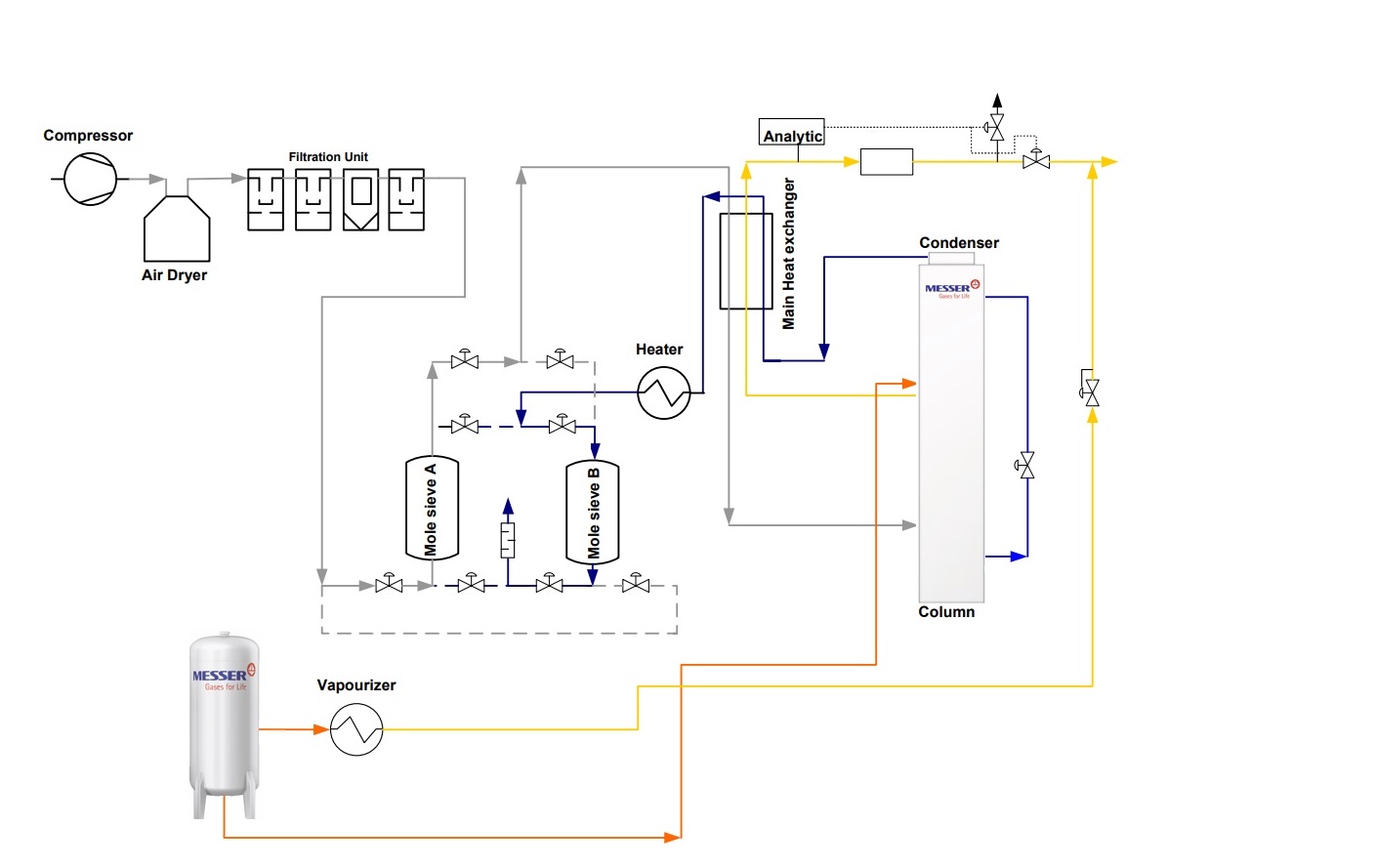

Diagram of a CryoGAN nitrogen generator

Powerful as a matter of principle Irrespective of their capacity, the basic principle is the same for all CryoGAN nitrogen generators and consists of the following components

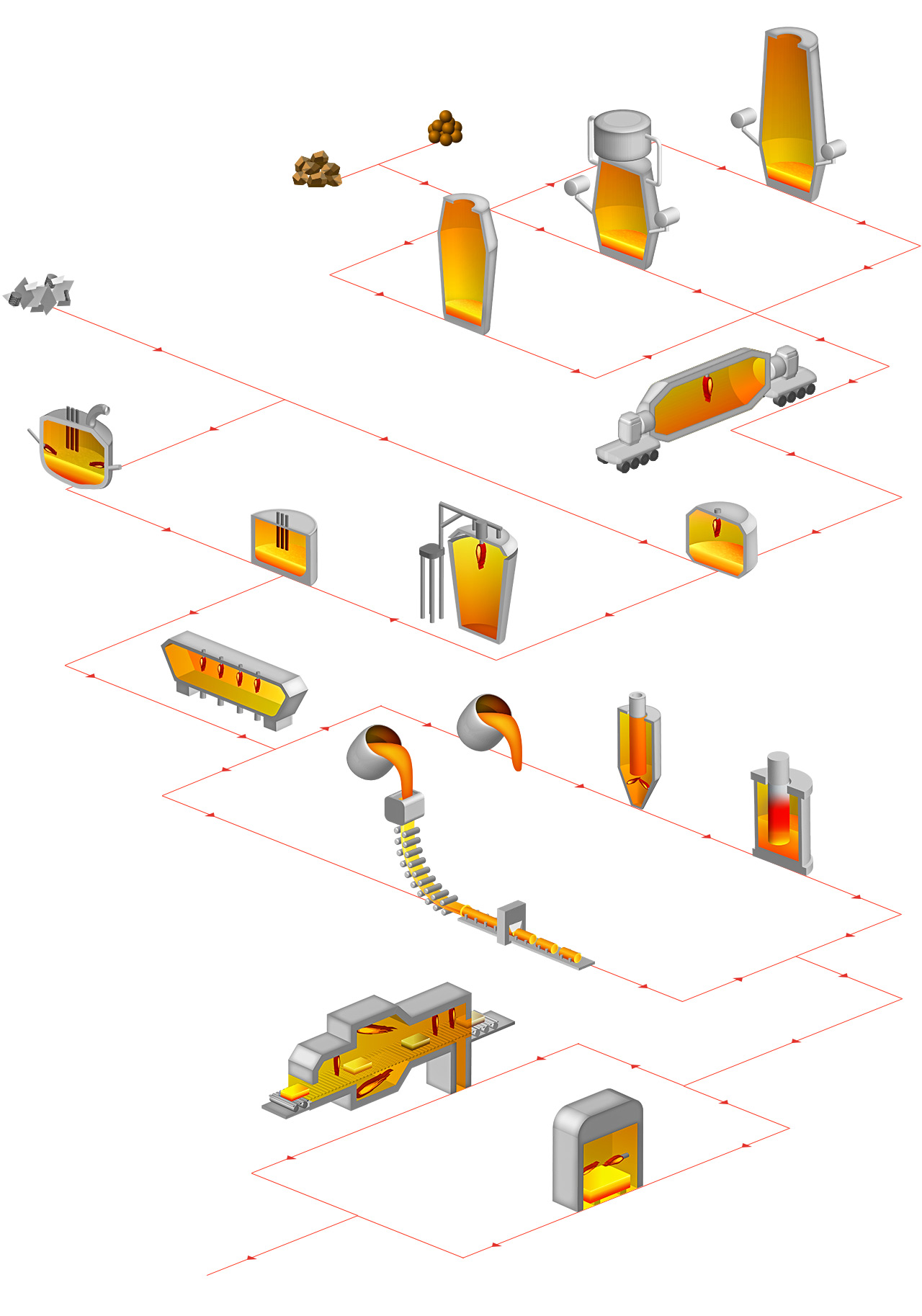

Steel processes

Is it possible to imagine a world without steel? No, steel is one of the essential materials in our society and we encounter it every day, whether as a paper clip, means of transportation or skyscrapers. The period of mass steel production began in the mid-19th century with developments from Bessemer, Thomas and Siemens - Martin. The advantage of pure oxygen for refining was already known at that time, but only became technically manageable 100 years later. Steel producers, research institutes and suppliers are working worldwide to improve product properties and manufacturing. Steel is made from iron ore or scrap.

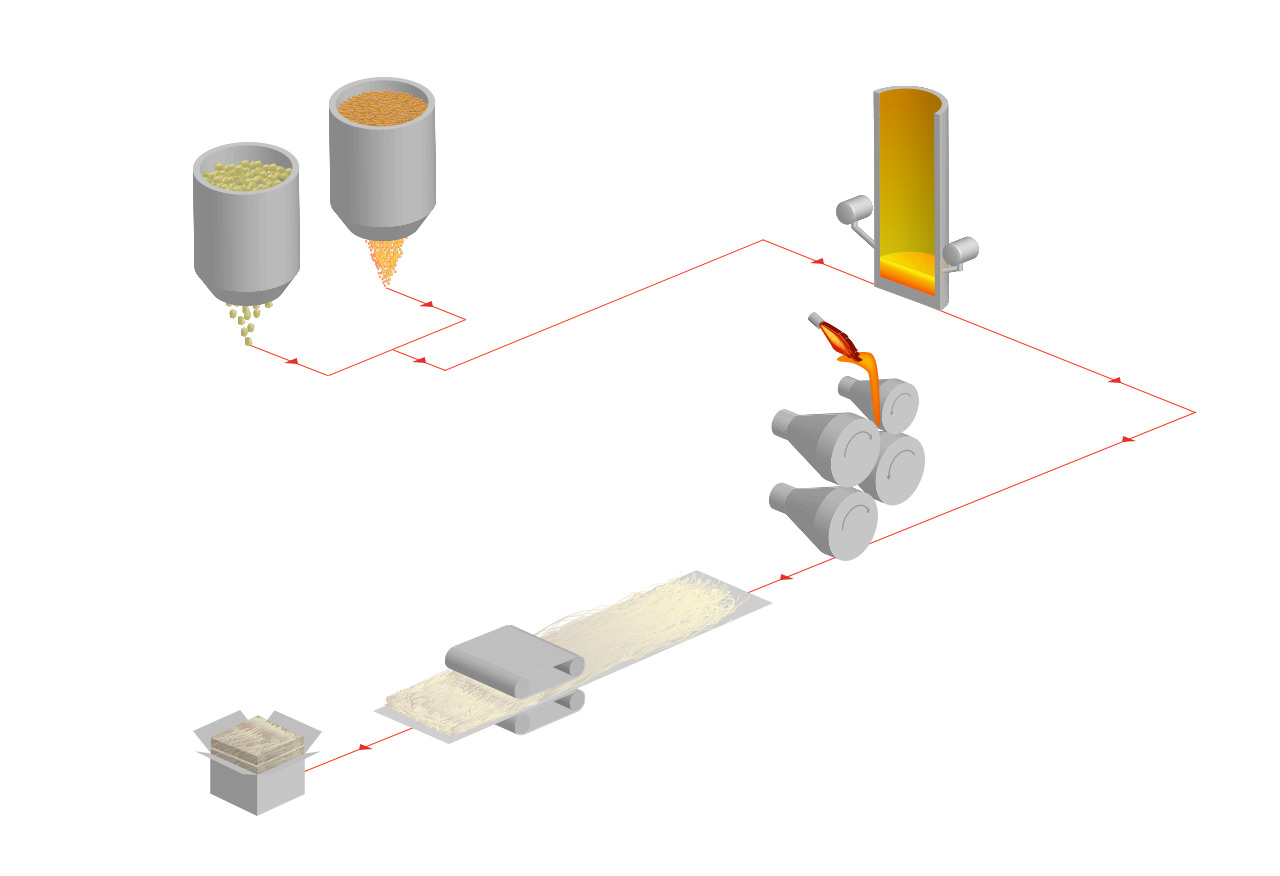

Stone wool production process

Mineral wool, also known as mineral fiber, mineral cotton, man-made mineral fibre (MMMF), and man-made vitreous fiber (MMVF), is a general name for fiber materials that are formed by spinning or drawing molten minerals (or "synthetic minerals" such as slag and ceramics). The nomenclature of these wool products is simply the parent/raw material name in prefix to wool. Wool from glass is glass wool, wool from rock is stone wool and so on. Specific mineral wool products are stone wool and slag wool. Europe also includes glass wool which, together with ceramic fiber, are completely man-made fibers. Applications of mineral wool include thermal insulation, filtration, soundproofing, and hydroponic growth medium.

Typical mineral wool composition