GAS APPLICATION

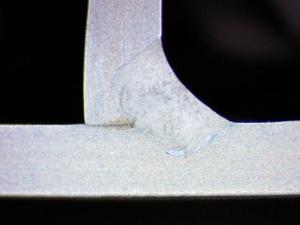

In the case of nitrogen-steam systems, the process parameters can be set individually. The steam provides the heat, and the nitrogen stabilizes the pressure to the desired level. As a result, nitrogen-steam systems have a shorter cycle time. In addition, the production rates increase while at the same time product quality improves, since local overheating of the steam is avoided. This protects the bladder and the rubber.

MESSER SOLUTION

Messer offers a team of experts who have relevant experience to implement this process improvement together with our customers. We accompany them from the design to the engineering stage right up to implementation at your plant. In addition, tests can be carried out promptly and cost-effectively with the existing equipment pool.